Let’s discuss the transformative role of Digital Twins and their integration with innovative technologies to revolutionize transaction processes.

The focal point is the seamless combination of Digital Twins, blockchain, and IoT (Internet of Things), driving autonomous transactions for heightened efficiency and reliability. As decision-makers navigate the complexities of modern business, we’ll aim to underscore the significance of embracing autonomous synergy.

The three pivotal technologies: Digital Twins, blockchain, and IoT. These technologies form the basis of autonomous transactions, with Digital Twins providing virtual representations, blockchain ensuring secure transactions, and IoT contributing real-time data.

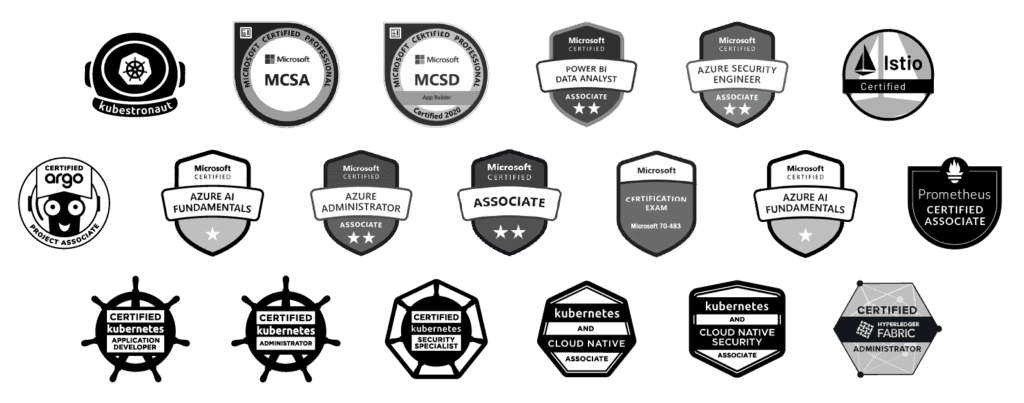

In this context, Veritas Automata’s Hivenet emerges as a powerful tool that enhances the digital chain of custody. Hivenet is a platform that amalgamates secure and efficient data management through the creation of digital chains of custody. Hivenet serves as a dynamic solution for businesses, enabling innovation and agility in today’s fast-paced digital environment.

Hivenet represents the digital chain of custody, integrating Kubernetes-based infrastructure, blockchain technology via Hyperledger Fabric, and advanced application architecture support. Tailored for organizations embracing cloud-native, blockchain, and edge technologies, Hivenet provides a comprehensive toolkit that transcends traditional cloud services when creating secure transactions.

Why it Matters: Because Life’s Too Short for Unanswered Questions!

Digital twins enable real-time, accurate representations of physical assets, processes, or systems through a combination of advanced technologies and methodologies. Here’s how they facilitate such precise monitoring, analysis, and optimization:

01. Data Integration and IoT: Digital Twins are built upon the integration of vast amounts of data from various sources, including IoT sensors, operational systems, and external environmental data. IoT sensors installed on physical assets collect real-time data on performance, environmental conditions, and operational parameters. This continuous flow of data into the Digital Twin ensures that the virtual model accurately reflects the current state of its physical counterpart.

02. Advanced Simulation and Modeling: At the core of a Digital Twin is a sophisticated simulation model that replicates the physical asset’s behavior under various conditions. This model can simulate physical phenomena, mechanical performance, and the impact of environmental factors using physics-based modeling, statistical methods, and machine learning algorithms. This allows for detailed analysis and scenario planning, helping decision-makers understand how assets will perform under different conditions.

03. Real-Time Analysis and Predictive Analytics: Digital Twins leverage real-time data analytics and predictive modeling to forecast future performance and identify potential issues before they occur. By analyzing trends and patterns in the data collected from the physical asset, the Digital Twin can predict wear and tear, maintenance needs, and potential system failures, enabling proactive measures to avoid downtime and extend the asset’s lifespan.

04. Visualization and Immersive Technologies: Digital Twins often incorporate advanced visualization tools, including 3D modeling and Augmented Reality (AR), to provide an intuitive and immersive view of the asset and its operations. This aids in better understanding complex systems, simplifying troubleshooting, and enhancing collaboration among teams by providing a common, detailed reference point.

05. Automated Control and Optimization: With the integration of AI and machine learning, Digital Twins can automate decision-making processes based on the real-time analysis of data. They can optimize operations by adjusting parameters in the physical world (through connected devices and control systems) to achieve desired outcomes, such as reducing energy consumption, maximizing throughput, or minimizing waste.

06. Integration with Business Systems: Digital Twins are not isolated systems; they are integrated with Enterprise Resource Planning (ERP), asset management, and Business Intelligence (BI) systems. This integration ensures that insights derived from the Digital Twin can directly inform business decisions, operational strategies, and financial planning, aligning technical capabilities with business objectives.

By choosing Hivenet, organizations invest in a strategic asset that significantly enhances operational agility. Hivenet’s commitment to security and efficiency empowers businesses to innovate and operate more dynamically, staying competitive and safe in the rapidly evolving digital world.